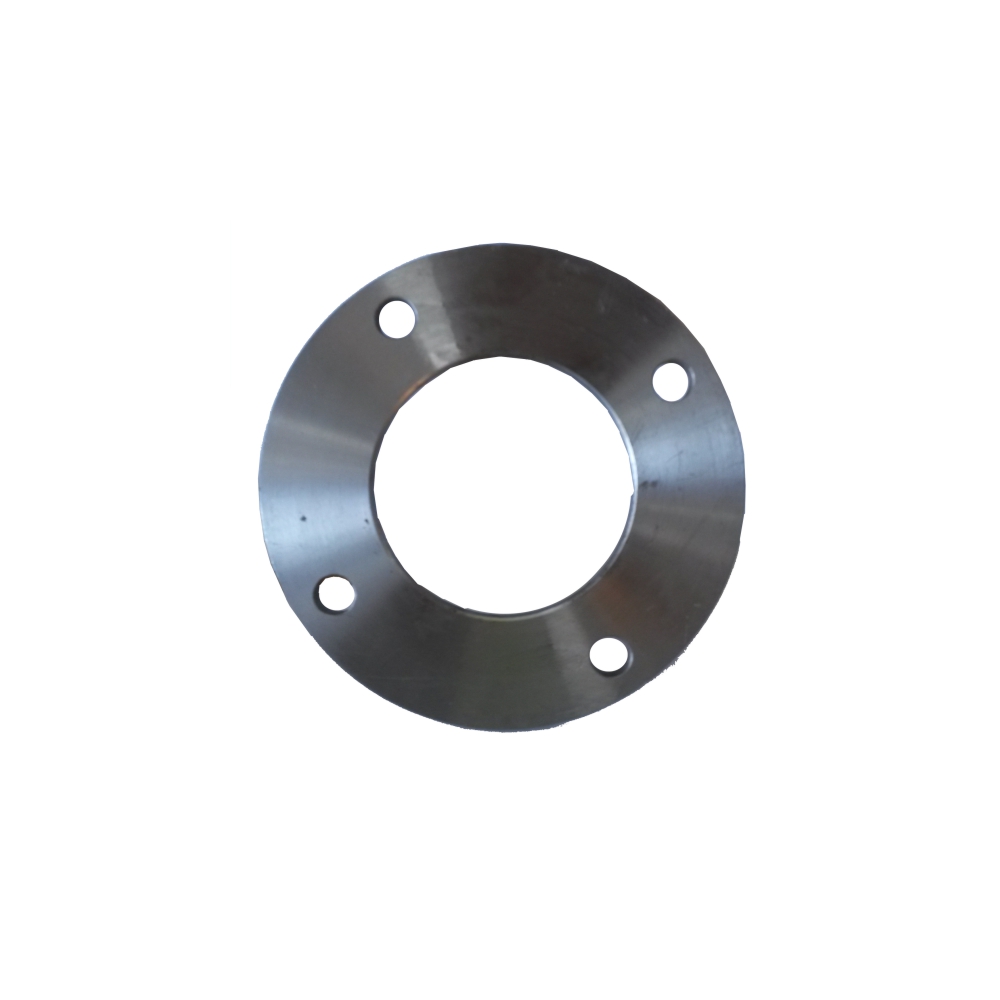

The calculated strength from a Slip-On flange under internal pressure is of the order of two-thirds that of Welding Neck flanges, and their life under fatigue is about one-third that of the latter. The connection with the pipe is done with 2 fillet welds, as well at the outside as also at the inside of the flange.

Features & Technical Data:

Maximum Temperature: 0-350°C

Tensile Strength: 375-460MPA

Hardness: HB120 – 140 (Brinell)

Elongation Rate: ≥26%

Suitable Applications: Water, Oil, Gas, Petro-Chemical

Material: Forged Carbon Steel

Description

Dimensions Table

| ITEM CODE | BSP | METRIC mm | D | C | T | H | K | NO. HOLES |

|---|---|---|---|---|---|---|---|---|

| 927/0040 | 1½” | 40 | 133.4 | 50 | 6.3 | 14.3 | 98.4 | 4 |

| 927/0050 | 2” | 50 | 152.4 | 62 | 7.9 | 17.5 | 114.3 | 4 |

| 927/0065 | 2½” | 65 | 165.1 | 78 | 7.9 | 17.5 | 127 | 4 |

| 927/0080 | 3” | 80 | 184.1 | 91 | 9.5 | 17.5 | 146 | 4 |

| 927/0100 | 4” | 100 | 215.9 | 116 | 9.5 | 17.5 | 177.8 | 4 |

| 927/0150 | 6″ | 150 | 279.4 | 168 | 12.7 | 17.5 | 235 | 8 |

| 927/0200 | 8″ | 200 | 336.6 | 221 | 12.7 | 17.5 | 292.1 | 8 |

| 927/0250 | 10″ | 250 | 406.4 | 276 | 15.9 | 22.2 | 355.6 | 8 |